How to compute for the losses found in transformers?

We mention in the previous articles the different types of internel energy dissipation of transformers. Here we will be showing you some basic formulas used in computing for the said losses;

1. The Core Loss of the Transformer

where: V1 - voltage rating

Io - exciting current in amps

cos0 - cosine of the angle between wattful current and exciting current

Rc - resistance representing the core loss

Ic - wattful current in amps

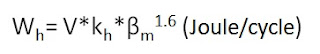

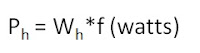

2. Steinmetz Law: Hysteresis Loss

where: V - core volume

kh - hysteresis constant (depending on the materials)

Bm - maximum flux density

1.6 - steinmetz constant

where: f - frequency

Ph - hysteresis loss in watts

3. Eddy-current Loss

where: Pe - eddy-current loss in watts

p - resistivity of the ferromagnetic material in ohm-meter

t - thickness of the lamination in meters

f - frequency in hertz

Bm - maximum flux density in Tesla

V - core volume in cu.meter

4. Core Loss with hysteresis and eddy-current componets

where: Ph - hysteresis loss

Pe - eddy-current loss

5. Copper (winding) Loss

where: I1 - current referred to primary

Ro - equivalent resistance referred to primary

The maximum efficiency of a transformer is said to be achieve when the winding loss is equal to the core loss or;

and, the load current at maximum efficiency can be computed by this formula;

These are some of the formulas used in computing for different transformer parameters especiall with respect to the energy dissipated.

fremerdisp-pe Melvin Magee click

ReplyDeleteexrammidon