EFFECTS OF TRANSFORMER LOADING TO LOSSES

Transformers, especially substation transformers are subjected everyday to loads that varies in any given period of time. The behaviour of its transformer loading is dependent to the nature of customers that are connected to it. The load profile of residential loads is not identical to the commercial ones the same with the commercial loads not identical to the industrial ones. It is also a given fact that a substation caters a mixture of these loads thus we can conclude that the transformer loading behaviour of one substation will not be necessarily similar to its adjacent substations.

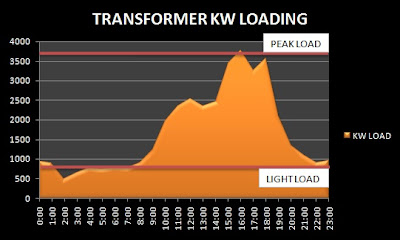

|

| Sample of Transformer Loading Profile |

These varying loads that are injected to the substation transformer are directly proportional to the losses it generates. We have discussed in the previous articles that substation transformer loss consist mainly of three known types; Load Loss, No-Load Loss and Auxiliary Loss. Since No-Load loss of a transformer is not affected by the load it carries, we will only be concerned with the Load and Auxiliary Loss for this analysis. Load loss, as what it tries to describe is losses that are primarily caused by the loading of the electrical equipment. Known to be true is that different level of loading in the transformer will also mean different levels of losses and all that only because of the I squared R formula.

To understand more about the effects of transformer loading to the winding loss, let us site an example on how different loadings will yield different losses.

Suppose we have a substation with a 33-MVA transformer having a self-cooled rating of 20MVA. Looking upon its nameplate rating, the transformer has a No-Load loss of 24kW and a Winding kW loss of 67kW at 20MVA Base.

During the light load period of its operation, it carries a load reaching 15MVA while during its peak it registers a 27MVA of load. With this given data, let us try to compare these two periods in the transformer operation with respect to the winding losses it generates.

In solving for the loss during these given times, two formulas can be used. One is the traditional way which is the 3 x (I squared R) formula since winding loss vary with the square of the load but in using this we still have to compute for the winding resistance of the transformer. The other way is the winding loss equation;

WINDING LOSSES = (MVA LOAD / TRANSFORMER SIZE IN MVA)^2 x (TRANSFORMER WINDING KW LOSS AT RATED LOAD)

Using the Winding Loss Formula, we now compute for the losses of the 15MVA and the 27MVA period for us to compare how the transformer loading affects the Load Loss of the transformer.

At the Light Load Period (15MVA)

WINDING LOSS = (15MVA/20MVA) 2 x 67 kW

WINDING LOSS = 37.69 kW

At the Peak Load Period (27MVA)

WINDING LOSS = (27MVA/20MVA) 2 x 67 kW

WINDING LOSS = 122.1 kW

Our result shows the effects of the transformer loading to the losses where the light load winding loss (37.69kW) is almost doubled compared to that of the winding loss during peak load (122.1kW). So, in summary, the no-load loss is unaffected regardless of the transformer loading while the load loss is dependent to the level of the transformer loading based upon its rated based MVA rating.

Voltage regulation with regards to the transformer loading can be either positive or negative in value, that is with the no-load voltage as reference, the change down in regulation as the load is applied, or with the full-load as reference and the change up in regulation as the load is reduced or removed.

ReplyDeletePower transformers in India | Transformer manufacturer in India