VOLTAGE REGULATORS IN DISTRIBUTION SYSTEM

Voltage Regulators used in Power Distribution System?

Voltage regulators affect the system efficiency in two ways. First, by maintaining proper voltage on the feeders they serve, regulators reduce losses on lines and distribution transformers supplied by the regulated voltage. Second, losses occur on the regulators themselves. Depending on regulator design, loading, and mode of operation, these losses can be quite high.

Regulation at Substations

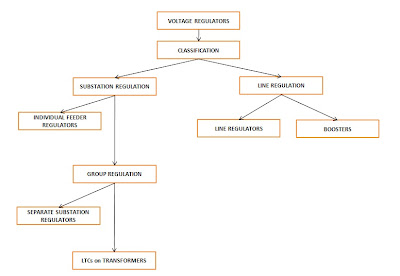

Two major decisions are involved in the choice of regulating equipment to be installed in distribution substations. First, the distributor must decide whether to provide separate regulation for each outgoing distribution feeder or whether some of the feeders will share regulating equipment. For modest-sized substations with only one substation transformer bank and three to five feeders, the decision may come down to the choice between regulating equipment for each feeder and a single, large regulating device serving all feeders. If the distributor decides to regulate all feeders as a group, providing only one regulator installation, it must make a second decision: whether to regulate by using a substation transformer load tap changer (LTC) or by using a separate regulating installation.

Types of Voltage Regulators

Shown below are the types of regulators used in distribution system each with its own purpose and function.

Comments

Post a Comment