SELECTION OF CONDUCTORS FOR OVERHEAD LINE DESIGN

What are the guidelines to be considered in selecting conductors for overhead line design?

What are the guidelines to be considered in selecting conductors for overhead line design?

Economically, conductors represent between 20 to 40% of the total cost of a line; consequently their selection is of prime importance. In earlier days of electrical power transmission, copper was mainly used as the material of overhead line conductors, however with the expansion of electricity networks, several factors, such as price, weight, availability and conductivity, have virtually compelled Overhead Line Design Engineers to concentrate on aluminium based conductors, eg.

AAC = All Aluminium Conductor

ACRS = All Aluminium Conductor Steel Reinforcement

AAAC = All Aluminium Alloy Conductor

ACRS = All Aluminium Conductor Steel Reinforcement

AAAC = All Aluminium Alloy Conductor

Steel conductors are still widely used as overhead earth wires and also as phase conductors on rural distribution lines, eg.

SC/GZ = Galvanised Steel Conductor

SC/AC = Aluminium Clad Steel Conductor

Phase Conductors

The conductors fulfil an electromechanical function; hence both the electrical and mechanical aspects are to be considered.

• Electrical parameters: The most important parameter affecting the choice of conductor is its resistance, because it influences voltage regulation, power loss and current rating. For AC lines, the diameter of a conductor affects the inductance and the capacities. Up to a voltage of 132kV, the above considerations are generally adequate, however at higher voltages, the above gradient on the conductor surface may require the selection of a conductor on the basis of its diameter, thus leading to the use of bundled conductor (ie. 2, 3 or 4 phase).

• Mechanical parameters: As already indicated, Aluminium based conductors represent the highest proportion of conductor usage. The advantageous mechanical properties of aluminium alloys have also been recognised for long time, but AAAC has always been more expensive than ACSR, for equivalent conductivities. However there are cases where initial cost is not the governing factor. One of these is the corrosion performance, since being monometallic, the risk of bimetallic corrosion between the aluminium and the zinc on the steel core are non-existent. Consequently AAAC conductors are used on lines in coastal areas.

Corrosion Performance

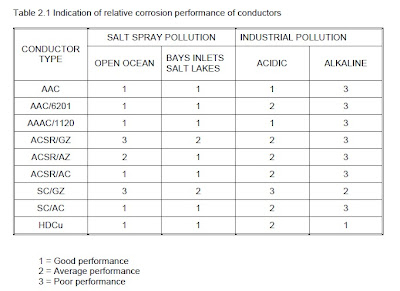

Table 2.1 provides an indication of the relative corrosion performance of various conductor types. The recommendations should be modified by local experience, for example, for salt spray pollution the relative distances from the source depend upon the prevailing winds and the terrain. Special circumstances such as crop dusting, which has been known to have severe effects, should also be taken into account.

Table 2.1 provides an indication of the relative corrosion performance of various conductor types. The recommendations should be modified by local experience, for example, for salt spray pollution the relative distances from the source depend upon the prevailing winds and the terrain. Special circumstances such as crop dusting, which has been known to have severe effects, should also be taken into account.

The lower the line, the lower the power load the wires are allowed to carry, so overhead line materials is must.

ReplyDeleteAs Timothy Thiele notes, the amount of voltage allowed in overhead lines and overhead line materials depends on the clearance (how high they are).

ReplyDeleteOver Head transmission line planning, routing, and design and overhead line materials supply within a stipulated time schedule is must.

ReplyDelete